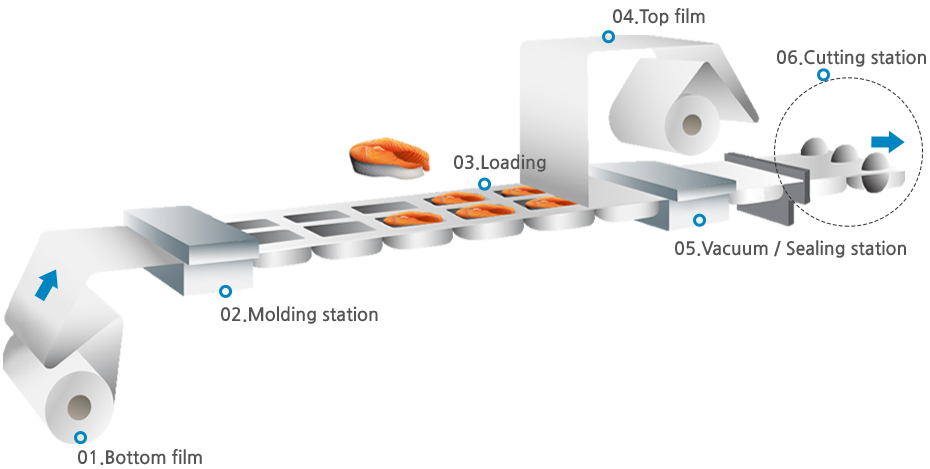

01: The film which can be formed by heat is supplied with uniform tension.

02: When the supplied bottom film is properly heated at the molding station, the container is molded to fit the frame.

03: Fill the molded container with the product to be packed manually or automatically..

04: The top film covers the container containing the product and then moves to the vacuum / sealing station with the bottom film. You can print expiration dates, product numbers, and so on.

05: Make a vacuum in the vacuum / sealing station and, if necessary, connect the top and bottom film with heat and pressure after the gas is filled.

You can choose from various packaging such as vacuum pack, gas replacement pack, steam flush pack, hot pack, and skin pack.

06: The finished product is cut in the cross direction and the proceeding direction, and it is possible to select the date cut, zigzag cut, dotted line cut according to the type.

Labeler function can be installed in this area.

We always offer professional solutions for packaging of agricultural / livestock products / marine products, medical and medical components, mechanical and electronic components. With high quality and high productivity, you can enhance your business competitiveness.

Ham, sausage, cheese, fish cake, fish, rice cake, vegetables, raw meat, jerky, raw meat, smoked meat, bread, etc.

Syringes, combs, surgical instrument kits, labyrinths, sterilizing tools, covers, hats, etc.

Bearings, plastic parts, various sanitary products, accessories, sanitary parts, etc.

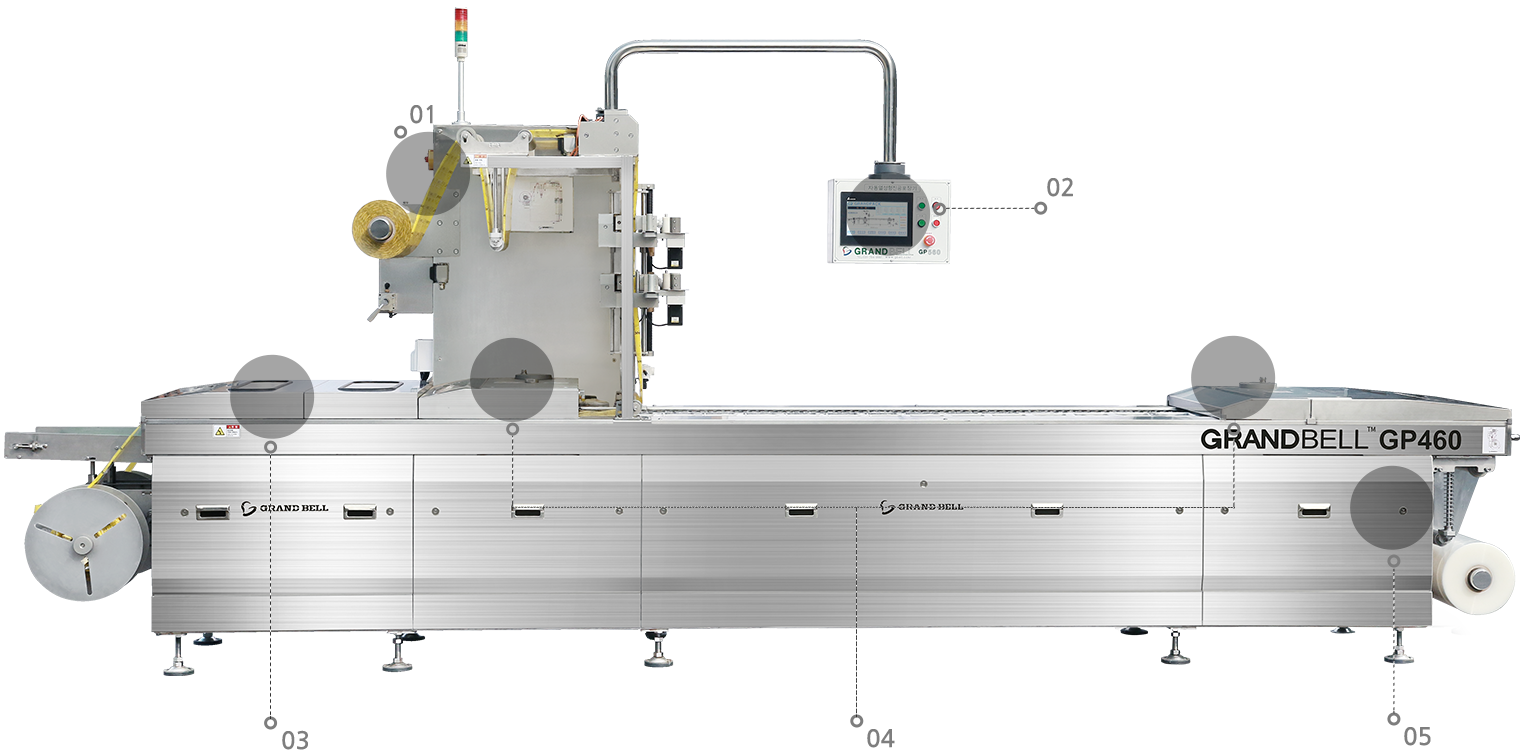

The large size model enables you to utilize various options efficiently and customized design according to your needs. It can be packed in various forms and can be mass-produced, which can increase productivity.

Specifications

| Size (mm) | 5600 * 980 * 1950 | ||

|---|---|---|---|

| Mold width (mm) | Max 420 | Power consumption (Kw/h) | 18~24 |

| Mold Pitch (mm) | Max 300 | Air supply pressure | 5Kg/Cm2 Over |

| Mold Depth (mm) | Max 70 | Machine weight (Kg) | 1200~1500 |

| Production (cycle/min) | 6~8 | Film Diameter (mm) | 400 |

| Product release type | Conveyor | Cooling water consumption | 0 or 10ℓ/min |

The world’s first skin packaging technique mounted on thermoform vacuum packaging machine

All parts can be disassembled and cleaned with water.

Designed to fit the body shape of the Orient, the worker’s fatigue can be minimized.

[Patent] Significant savings by converting the ultra high thermoforming packing machine into facility investment. (option)

Thermoforming Vacuum packing, steel vacuum, vacuum, cup sealer, MAP etc. (optional)

Options such as automatic feeder, filling machine, and labeler are available.